Operation principle of PSA Nitrogen Generator

Pressure-swing adsorbing air separating nitrogen making (abbreviated as P.S.A nitrogen making) is an advanced air separating technology, with high-quality carbon molecule sieve (CMS)as adsorbent, adopts normal temperature pressure-swing adsorbing principle(PSA) to separate air to fetch high purity nitrogen.

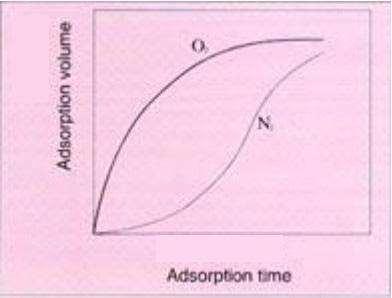

The speed of diffusion of two kinds of gas molecules of oxygen and

nitrogen on the surface of molecule sieve is different, the gas molecule

(O2) smaller in diameter spreads faster, more entry into millipore

of carbon molecules sieve, the relatively slower gas molecule (N2)

bigger in diameter spreads slowly, less enter into millipore of

carbon molecule sieve. Utilizing the difference of this kind of selective

absorption of carbon molecule sieve toward nitrogen and oxygen,

causing oxygen to enrich in adsorbed phase in short time, the nitrogen to enrich in gas phase, so the oxygen and nitrogen is separated, getting the gas phase richment of nitrogen under PSA condition.

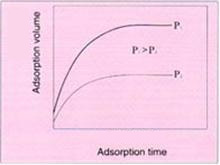

Change difference curve of adsorbing quantity at one time under different pressures of oxygen and nitrogen by carbon molecule sieve:

After some time, the adsorbtion of oxygen by carbon molecule sieve reaches balance, according to characteristics of different adsorbing amount towards adsorbed gas under different pressures by carbon molecule sieve, reduce pressure to remove the adsorbtion of oxygen by carbon molecule sieve, this course is regeneration.

Pressure-swing adsorbing air separating nitrogen making machine(abbreviated as P.S.A nitrogen making machine) is the nitrogen generating equipment designed, manufactured according to pressure-swing adsorbing technology. Normally use two adsorption towers connected in parallel, to control time sequence strictly by full-automatic control system according to specific programmable program, conducting pressurized adsorption and decompression regeneration alternately, finishing the separation of nitrogen with oxygen, to obtain high purity nitrogen required.

PSA nitrogen gas generator is composed of five parts: A.Compressed Air Purification System, B.Air Tank System, C.O2/N2 Separation System, D. Nitrogen Buffer System, E.Electrical Control System.

The flow of producing nitrogen gas is composed mainly of four steps:

v Air compressor provides compressed air with certain pressure;

v Air purification system purifies compressed air by removing the dust, oil and water;

v Oxygen and nitrogen separation system produce qualified nitrogen gas with PSA technology;

v Nitrogen buffer system provides a stable source for follow-up equipment by the storage of nitrogen gas.

Air compressor compress the air through the consumption of electricity , for providing stable and sustainable raw materials for follow-up of oxygen and nitrogen separation system.

Compressed air enters the air purification systems from compressor. The role of air-purification system is to remove dust, water and oil by the three filters, freeze-drying machine, and effective degreaser. Degreasing which is to protect the core component of nitrogen machine - carbon molecular sieve, to avoid oil poisoning.

Purified compressed air enter the separation of oxygen and nitrogen, oxygen and nitrogen separation system equipped with a carbon molecular sieve. The two adsorption tower worked alternatively to provide the stable production to meet the requirements of the user.